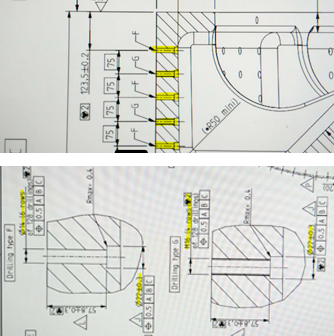

A manufacturer of wind rotors was looking for a more efficient and stable solution for the application of back spotfaces to bores.

An Efficient and Reliable Solution for Back Spotfaces on a Wind Rotor Wheel

Back To Case Studies

An Efficient and Reliable Solution for Back Spotfaces on a Wind Rotor Wheel

Sep 27, 2017

Challenge:

Application details:

- Main bore: Ø14.0 mm

- Counterbore diameter: Ø22.0 mm

- Material: GG40

- Machining: Horizontally with internal coolant

- Machine: Gantry Boring and Milling Machine Center

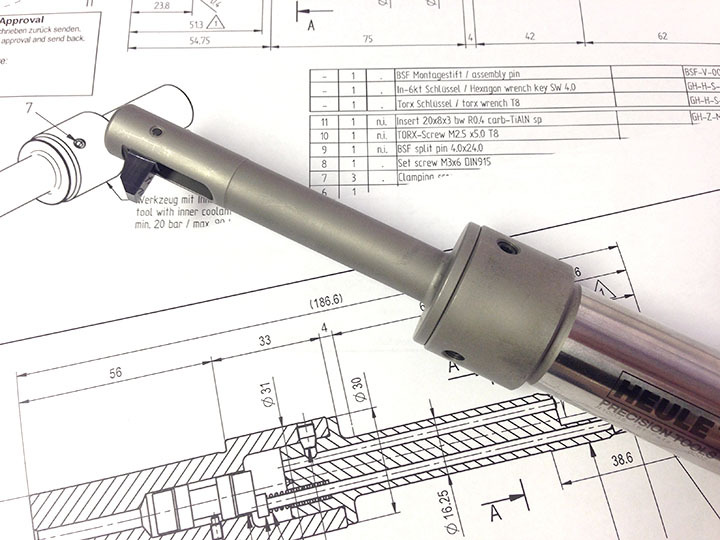

Solution:

HEULE recommended the BSF tool with a working length of 80 mm, together with a TiAlN coated carbide blade type BSF-M-E-1A-5.0.

Machining parameters:

- Speed: N=500 rev/min

- Feed: F=20 mm/min

- Coolant: Internal coolant

Results:

By replacing their old tool, which needed pre-adjustments, this customer found more stability and a better process capability. The better stability led to a longer blade life for the tool. The customer is very happy with the solution and noted that their process is more efficient, precise, and safe.

Interested in the BSF back spotfacing tool? Visit the BSF product page for more info.