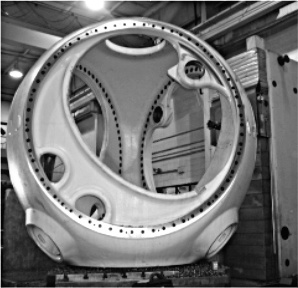

Applying Counterbores to a Wind Mill Blade Hub

Challenge:

This customer in the energy industry became aware of HEULE products at a major trade show. In the course of the following discussion he explained the details of his application. Soon was it obvious that the present process using a manually pluggable back spot facer offered some optimization potential.

Application details:

- Production volume: 1 to 2 hubs per week (198 counterbores/hub)

- Bore diameter: Ø39.0 mm

- Diameter back counterbore: Ø75.0 mm

- Counterbore depth: up to 15.0 mm (interrupted cut due to casting variance)

- Material: Cast iron

- Machine: large vertical boring mill

Solution:

Due to the large bore diameter and the diameter of the back counterbore, HEULE's GH-E tool was used. The GH-E tool traverses the bore from the front, extends the blade and then applies the counterbore. It retracts the blade into the bladehousing again and moves out of the bore.

Tool: GH-E 50

Blade: Indexable insert

Machining parameters:

- Speed: 390 rev/min

- Feed: 0.1 mm/rev

Results:

The customer saves over 12 hours per part over the previous operation.

Interested in a GH-E tool? Visit the Contact Us!