Applying Counterbores to an Aluminum Cylinder Head in One Operation

Back To Case Studies

Applying Counterbores to an Aluminum Cylinder Head in One Operation

Oct 9, 2017

Challenge:

A manufacturer of motorsport engines was looking for a cost-effective solution for the application of counterbores.

Application Details:

- Through hole: Ø12.6mm

- Counterbore backward: Ø22.0mm

- Material: Aluminium die cast

Solution:

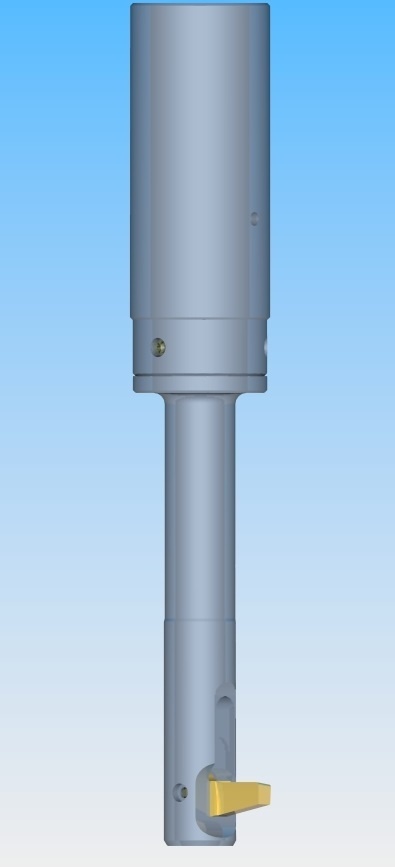

We have recommended our efficient HEULE BSF Back spot facing tool. For this counterbore, a customized BSF tool with a special working length of 80 mm has been designed.

Machining parameter:

Speed 2000 rpm, Cutting speed vc 140 m/min.

Feed 0.05 mm/rev.

To operate the BSF tool, an internal coolant with 20 bar pressure minimum is required.

Results:

By using the HEULE back spot facing tool the workpiece can be machined fully in one setup without reclamping or additional process step.

The customer is very satisfied by the result and the achieved time savings. The high spindle speed reduces the fluttering of the blade due to the interrupted cut considerably.

Interested in the BSF back spotfacing tool? Visit the BSF product page for more info.