Automating Cross Hole Deburring on a Hydraulic Component

Challenge:

A manufacturer of hydraulic components and fittings was looking for a more efficient and safer deburring solution for the cross hole of a ball valve. The goal was to automate the process and eliminate the tedious and time-consuming work of removing the burrs of the bore edge by hand with a brush.

Application Details

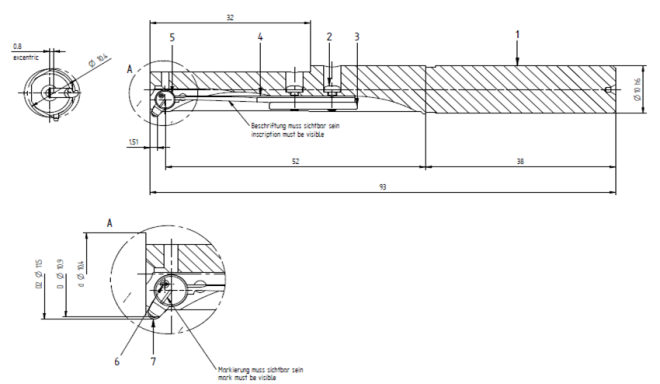

- Cross bore / lateral bore: Ø10.4 mm

- Main bore: Ø10.4 mm

- Material: SS316

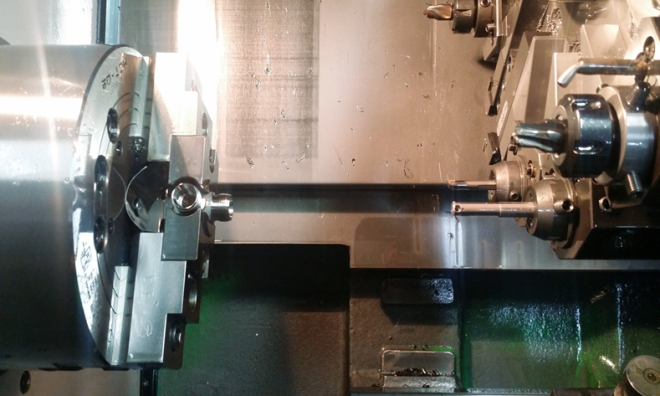

- Machine: DOOSAN CNC Center

Solution

The deburring of crossbores with bore-Ø-ratio of 1:1 represented a particular challenge for HEULE. The solutions that were available so far could not cope with the extreme sloping of a 1:1 bore and a completely new approach was needed. HEULE found the answer to the problem by making use of new machine capabilities and by developing a special version of the COFA tool (the new COFA-X).

Machining parameters:

- Speed: 10 m/min

- Feed: 0.06 mm/U

- Coolant: external coolant

Results

The fact that the deburring could be carried out in an automated process together with a considerable improvement in reliability resulted in significant savings and product quality. After the initial pilot project, the manufacturer was able to continue with high volume production of more similar T pieces.

Interested in the COFA-X for cross hole deburring? Visit the COFA-X product page for more info.