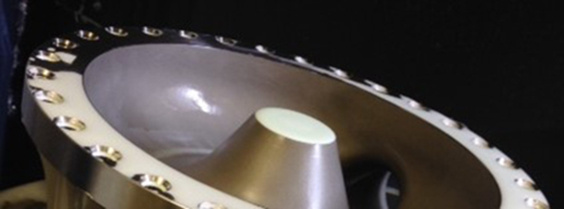

Back Spotfacing in Inconel 718 on an Aircraft Component

Challenge

An aerospace manufacturer was machining 30 back spot facings in a component made of Inconel 718 for some years. To do this, the part needed to be set up several times because of the poor accessability of the bores. Countersinks were carried out by a box column drill. For the other counterbores, he used a counterbore tool with a plug-in head for the back bore machining. The process time amounted to approx. 6 hours for one component. His goal was to simply speed up this process. Due to the very demanding material and the difficulty of accessing the machining spots, the customer was very skeptical with regard to new solutions.

Application Details

- Material: Inconel 718

- Counterbore diameter: Ø13.0 mm

- Counterbore depth: 0.7 mm

- Bore diameter: Ø6.6 mm

- Material thickness: 10.7 mm

- Angle to surface: 180 Degrees (Cast skin)

- Number of bores: 30

- Machine: 5-axis machining center

HEULE proposed its BSF tool with a working length of 15 mm equipped with a blade type BSF-M-1175 with X special coating.

Machining parameters:

- Speed: N = 300 U/min.

- Feed: F = 0.015mm/U

- Coolant: Inner and outer coolant

Results

The customer expectation was to produce 10 to 15 back spot facings with one blade, so that he would not need more than two blades per part.

With a uptime of 25 back spot facings per blade and a cycle time of 55 sec., the BSF tool exceeded his expectations considerably. Besides, the stability of the process could be improved because of the reduction to one single setup and by the omission of manual operations.

Being able to produce the part now in 35 minutes instead of 6 hours, the customer is not only satisfied but enthusiastic about the new solution.

Interested in a BSF back spotfacing tool? Visit our BSF product page for more info.