Combining Drilling, Deburring, Chamfering, and Countersinking on an Aluminum Wheel Valve Hole

Combining Drilling, Deburring, Chamfering, and Countersinking on an Aluminum Wheel Valve Hole

Challenge:

This customer produces approximately 800,000 aluminum wheels for the automotive industry each year. They were looking for a more cost-effective and efficient solution to producing valve holes that would not require turning of the work piece. Previously, the valve holes were produced by stepped drills and the bore ø11.6 on the back was deburred manually because it was inaccessible on the backside. According to the customer, the resharpening of the stepped drill was very complicated and time-consuming.

Application Details:

- Valve hole Ø11.6mm

- Countersink forward Ø16.25mm

- Chamfer backward Ø13.1mm x 90º

- Material Aluminium ALMg3Si7.

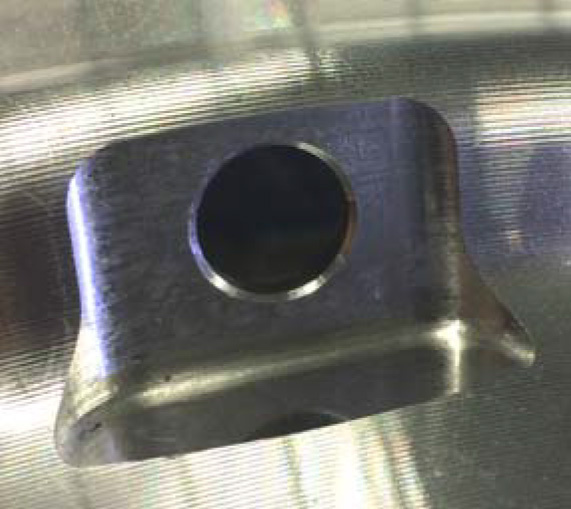

Valve hole: Forward Machining

Valve hole: Backward machining

Solution:

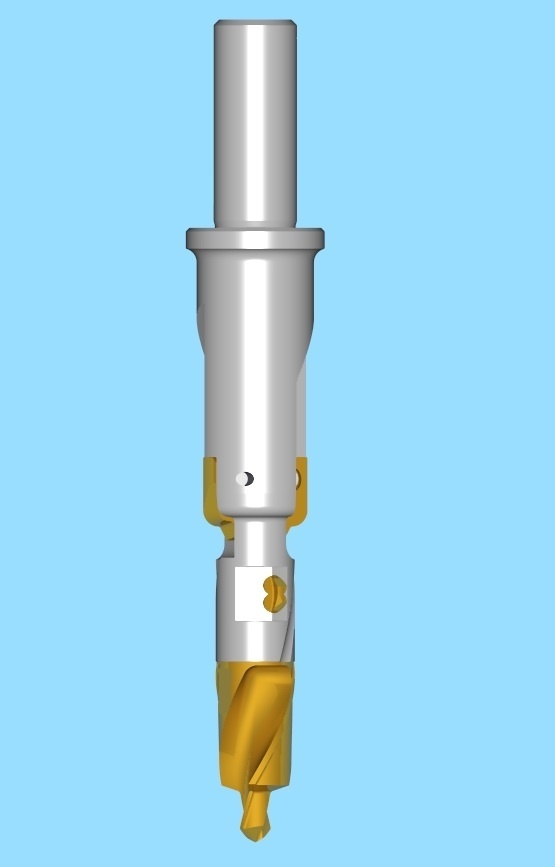

The solution from HEULE is a VEX-S Combination Drilling-Chamfering-Tool which has been tailored to the specific needs of the customer. The tool is capable to machine the 3 form elements in one operation and without further tool changes.

The deburring at the back is carried out by the proven SNAP function priniciple whereas indexable inserts made of carbide are applied for the shaped chamfer at the the front side of the bore.

Machining parameters:

Drilling and countersinking forward:

Speed 2750 rpm, Cutting speed vc 100 m/min,

Feed 0.2 mm/rev.

Chamfering backward:

Speed 2750 rpm, Cutting speed vc 115 m/min,

Feed 0.15 mm/rev.

Results:

The customer is very pleased by the reached result and production time. The new solution eliminates the manual deburring operation and the bore is manufactured completely by machine. The blades can be replaced easily and without readjustment of the machine.

Interested in VEX-S tool for drilling/deburring? Visit the VEX-S product page for more info.