Combining Operations to Machine a Mounting Bore

Challenge:

A manufacturer in the automotive industry produces about 12 million aluminium wheels for passenger vehicles per year. The customer was looking for a solution to produce the wheel mounting bore cost-effectively in one operation without having to turn the workpiece.

Application Details:

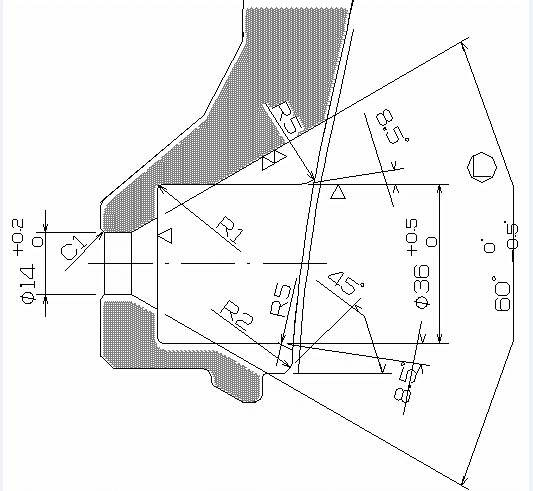

- Through bore: Ø14.0mm

- Counterbore forward: Ø36.0 mm

- 60° Sinking forward on the bore: Ø14.0 mm

- Back chamfer: 1.0 mm x 45º

- Material: aluminium

Solution:

The solution from HEULE is a VEX-P combined drill and countersink tool which has been specially adapted for the customer. In one pass and without any further tool change the four form elements can be machined.

The back deburring is executed by the proven SNAP principle.

For the forward counterbore a WSP plate made out of carbide is used.

Machining parameters:

Drill operation:

Speed 3500 rev/min, cutting speed vc 155 m/Min, working feed 0.3 mm/rev

Sinking forward / chamfering backward:

Speed 2800 rev/min, cutting speed vc 140 m/min, working feed 0.1 - 0.15 mm/rev

Results:

The production of bores and counterbores in aluminium wheels required the use of four different tools. Furthermore, the operation plan included one turning of the workpiece. The maintenance effort and the down time for the readjustment of the repaired tools were considerable. The high costs for the existing tools and the non-guaranteed process capability have been reason enough to rethink the present production sequence. The customer is very satisfied by the result and the achieved savings of time and money.

Interested in combining operations to save time and money? Visit the VEX-P product page for more info.