Eliminating Manual Deburring of a Steering Column Component

Challenge

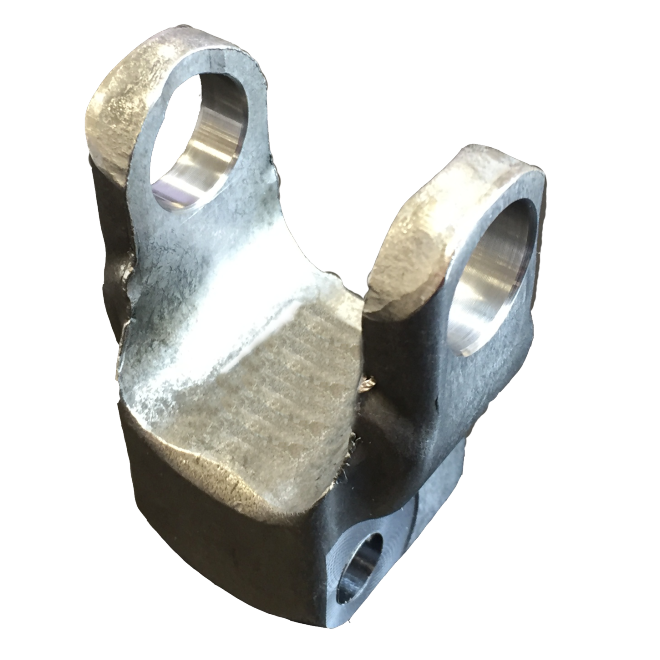

A precision machining subcontractor to the automotive industry used to deburr a fork laboriously by hand. The fork is part of the steering column. Faced with the problem that the manual deburring was too time-consuming and that it became a bottle neck in the production process, the company set out to look for a new solution.

Application Details

- Bore-Ø: 15.0 mm

- Deburr size: max. 0.3 mm

- Material: Steel

- Machine: Hermle Milling Center

- Machining: axially

- Cooling: external cooling, 30 bar pressure

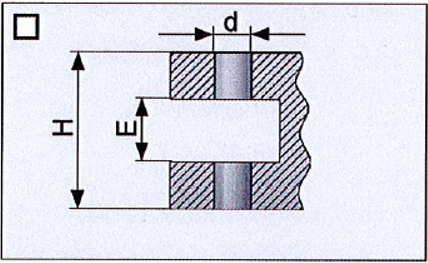

- Dimensions: d = 15.0 mm, H = 42.0 mm, E = 28.0 mm

- Production volume: 200,000 bores per year

Solution

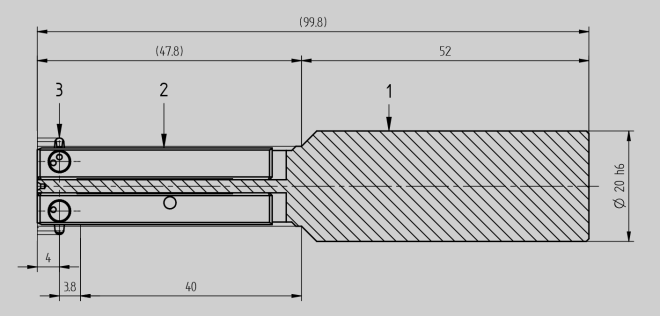

The deburring of the fork piece is a regular application of the COFA tool. The customer's requirement to reduce the process time as much as possible led to a special solution although the diameter of 15.0 mm could be easily deburred by a standard COFA tool. In order to be able to work with a maximal work speed HEULE proposed a double-cassette-tool. As the name implies it works with two blades at the same time.

Tool: Double-cassette-tool COFA C6

Blade: C6-M-0006-T

Machining parameters:

- Speed: 1000 rev./min.

- Feed: 0.8 mm/rev.

Results

As explained by the customer, the main benefit is the now process capable chamfer as well as the replacement of the manual secondary work and the resulting time gain.The machine operator is overjoyed that he no longer needs to manual deburr the part.

Interested in the COFA deburring tool? Visit the COFA product page for more info.