Producing Quality Chamfers on Car Hydraulic Components

Challenge:

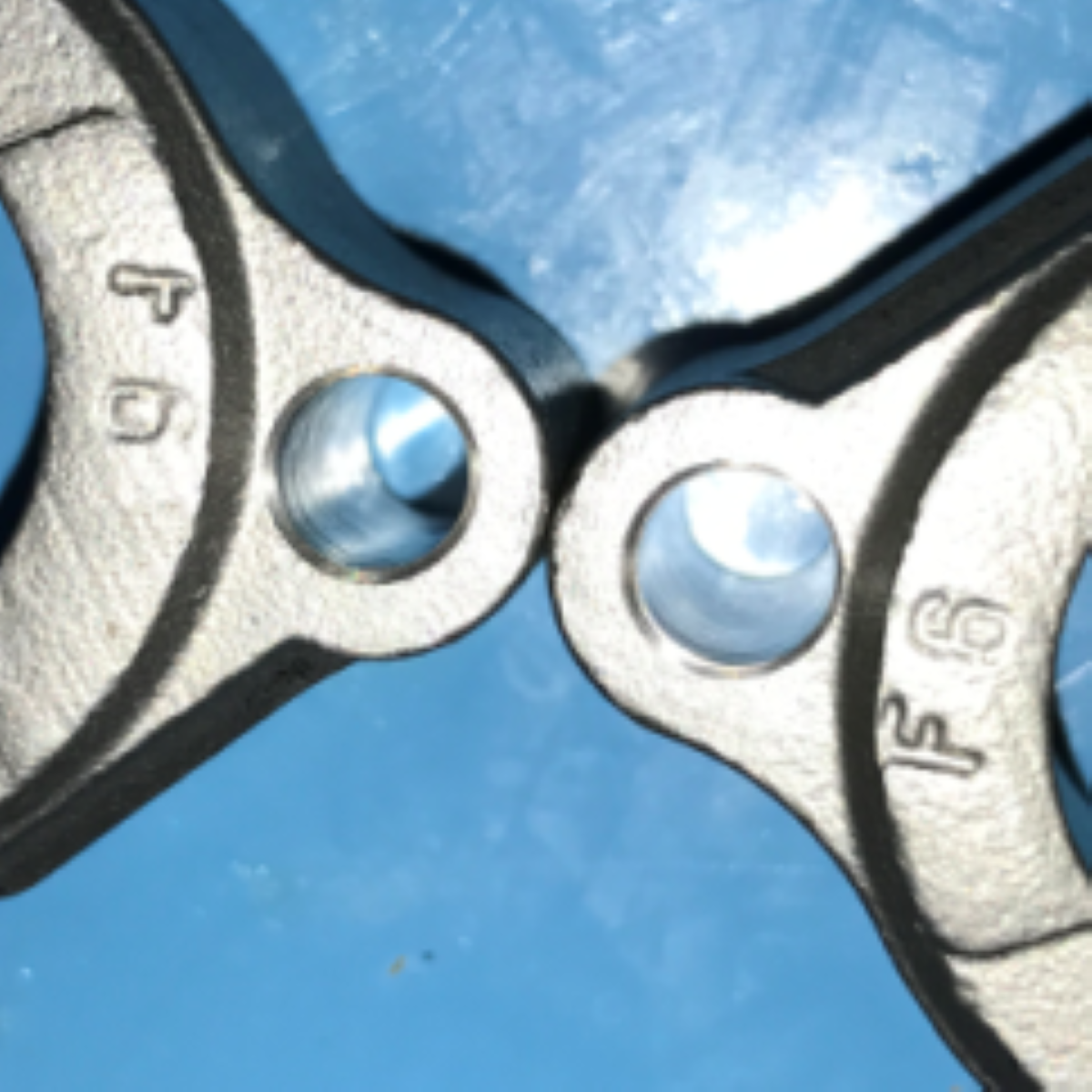

A manufacturer of car hydraulics components faced the problem that their solid carbide chamfer tool did not produce the required chamfers in the desired quality on the cast surface.

Application details:

- Bore-Ø: 6.7 mm

- max. Chamfer-Ø on front and backside of the bore: 7.0 mm

- Material: Cast steel 304 stainless

- Volume: 50,000 parts per year

- Machine: MAZAK Vertical machining center

- Machining: vertical

- Coolant: external coolant

Solution:

- Tool: SNAP5/6.5

- Blade: GH-Q-M-30207

Machining parameters:

- Speed: 1800 rev./min.

- Feed: 0.12 mm/rev.

Results:

The SNAP tool is producing the chamfer on the desired quality level constantly.

Furthermore, the production employees found out that the adjustment of the SNAP tool is much easier than before.

Interested in the SNAP chamfering tool? Visit the SNAP product page for more info.