Case Studies

Showing Entries with tag "Steel"

Entry Tags (33 found)

Aerospace Aluminum Automotive Back Counterboring Brass BSF Cast Iron Chamfering Cobalt-Chromium Alloy COFA COFA-X Composite Counterboring Countersinking Cross Hole Deburring Deburring DEFA Drilling Energy GH/E Heavy Equipment Inconel Medical Nickel Polyether Ketone (PEEK) Precision Machining SNAP SOLO Spotfacing Steel VEX-P VEX-S X-Bores

A manufacturer in the energy industry had to resort to time-consuming manual deburring when a competitor’s tool failed to do the job. Deburring the part outside the machine took approximately 9 minute...

A hydraulics manufacturer was able to reduce production costs and eliminate manual deburring using HEULE's X-Bores technology to deburr complex cross bores.

Deburring 1:1 Ratio Oil Bores on a Crankshaft

A manufacturer was deburring the oil bores on these crankshafts by hand for a large automotive customer. After repeated complaints from the customer, the manufacturer set out to look for a more reliab...

A high-volume motorcycle manufacturer that was producing 480 lower fork arm brackets per day was seeking an efficient back counterbore tool. Their current tool was having issues with tool breakage an...

Deburring Bores on Hard-to-Reach Irregular Surfaces

A manufacturer of V-8 crankshafts was faced with the challenge of deburring a main bore that broke into seven different surfaces, some of which were angled/irregular. They needed a tool solution that...

Saving 34% Cycle Time on a Sprocket Wheel

A subcontracting company to the automotive and the fittings industry produces a range of components such as flanges, sprockets and drive shafts and was looking for a solution to reduce cycle time ...

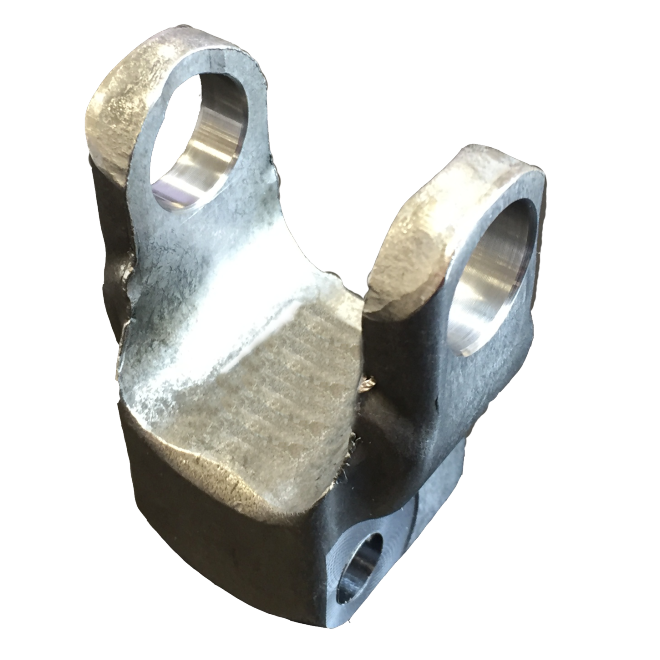

A subcontractor to the automotive industry used to deburr a fork laboriously by hand. The fork is part of the steering column. Faced with the problem that the manual deburring was too time-consuming a...

A manufacturer of hydraulic components and fittings was looking for a more efficient and safer deburring solution for the cross hole of a ball valve. The goal was to automate the process and eliminate...

Countersinking Bores for a Tractor Component

A major heavy equipment manufacturer was looking for a solution to produce countersinks on bores for a gear component on a tractor.

A precision machining supplier to the automotive industry who produces more than 1 million common rails per year was looking for a solution to automate the back deburring of a low pressure bore.