SOLO: Spotfacing & Counterboring

Swiss Precision Since 1961

SOLO: The Ultimate Solution for Front & Back Spotfacing and Counterboring

Unlock unparalleled efficiency and robust performance with the SOLO tool, the leading choice for automated front and back spotfacing and counterboring operations. This single-operation tool, engineered for precision and reliability, effortlessly handles front and/or back counterboring and spotfacing without the need to rotate the workpiece.

Key Features:

- Powerful Performance: Experience the market's most robust and fastest automated back boring capability with SOLO.

- Superior Efficiency: Designed with a blade that extends and retracts radially via centrifugal force, SOLO enhances your production speed and reduces downtime.

- Optimal Compatibility: Perfectly suited for CNC, transfer, dial, and multi-spindle machines, enhancing its versatility across various manufacturing settings.

- Maintenance-Free Operation: The fully enclosed head design prevents coolant contamination and ensures a clean, maintenance-free operation.

- Innovative Blade System: Features a pin-driven cutting blade that prevents chip jamming, coupled with an easy-to-handle quick-change blade system for rapid adjustments.

- Cost-Effective: Offers an exceptional price-performance ratio, ensuring value for your investment without compromising quality.

- Customizable Tooling System: Each SOLO tool is tailor-made to your specifications, capable of incorporating multiple features like indexable countersinks and form countersinks for comprehensive machining solutions.

Industry Applications:

The SOLO tool is highly regarded in critical industries such as Aerospace, Automotive, Energy, and Heavy Equipment/Large Parts, where precision and durability are paramount.

Transform Your Machining Operations:

With the SOLO Tooling System, expect a seamless integration into your production line that promises not only to meet but exceed your machining expectations. Customize your SOLO tool to adapt to any manufacturing challenge, making it a versatile and indispensable part of your tooling arsenal.

How Does the SOLO Tool System Operate?

The SOLO tool series comprises two dynamic models, the SOLO 1900 and the SOLO 2, each designed to optimize front and back counterboring and spotfacing operations with precision and efficiency.

SOLO 1900: Precision Through Innovation

- Mechanism: This model operates with two centrifugal weights housed within a sealed tool head. When reaching an activation speed of 1900 RPM, the weights expand outward, engaging a gearwheel that in turn extends the cutting blade via a blade control mechanism.

- Operation: As spindle activity ceases, a built-in pull-back spring retracts the centrifugal weights and consequently, the blade, ensuring a safe and clean withdrawal.

- Capability: It achieves counterbore sizes up to twice the bore diameter minus 1mm, supporting applications up to a 30mm through-hole diameter.

SOLO 2: Advanced and Versatile

- Mechanism: Similar in design to the SOLO 1900 but functioning inversely, the SOLO 2 activates at a speed of 2000 RPM or higher for blade retraction. Below 1500 RPM, the weights revert to center, securing the blade in a precise cutting position.

- Enhancements: For larger bore applications, exceeding approximately 22mm, the optional SOLO S2 model offers an expanded tool head, facilitating greater scope and depth in machining tasks.

SOLO-L: Large Back Counterbores

- Mechanism: The SOLO-L tool system features a straightforward yet robust design that ensures reliability and efficiency in spotfacing and counterboring operations. The tool operates with a unique blade housing and control mechanism tailored to the user's specific requirements.

- Operation: The SOLO-L can produce counterbores up to a maximum of 1.95 times the bore diameter, handling bores ranging from 25.0 mm to 45.0 mm in diameter. Its design emphasizes process reliability and simplicity, guaranteeing optimal machining results with maximum operating efficiency.

- Capability: With the ability to adapt to customer-specific needs, the SOLO-L is suitable for diverse industrial applications, particularly where larger bore sizes are required. Its consistent performance makes it an excellent choice for achieving precise and efficient machining outcomes.

Optimized Machining Solutions: The SOLO-L model, along with the SOLO 1900 and SOLO 2, expands your machining capabilities, providing a robust and reliable solution for various industrial applications. For detailed specifications and to explore which model suits your needs, please contact us.

View more catalogs/brochures, videos, and technical information for SOLO

How Do I Order SOLO?

Each SOLO tool consists of two components:

1. Standard tool head with integral shank - This tool head is of standard design and is the base element for all applications with bore diameters 8 to 30mm.

2. Custom Components - Housing pilots, control mechanism and cutting blades are optimized per the desired back bore application and are customized to suit the needs of our customers.

Simply submit the SOLO Application Data Sheet with your application information for our engineering team to review. With each order, approval prints will be supplied to the end user within one week of order.

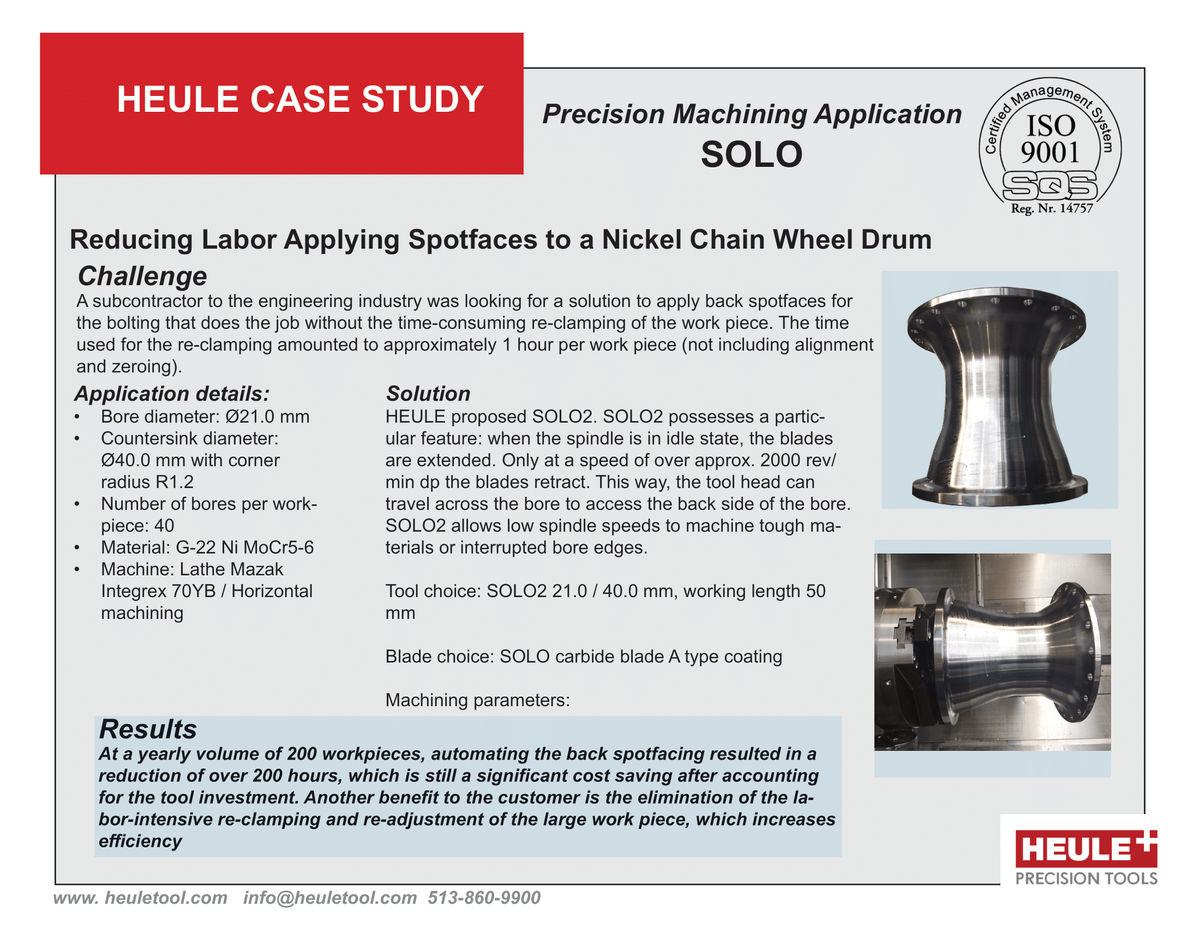

SOLO Case Study

Reducing Labor Applying Spotfaces to a Nickel Chain Wheel Drum

"By going with the HEULE SOLO Back counterbore tool, our end user documented a $13,249.55 per machine yearly cost savings. With 5 machines, this equals $66,247.75 annual cost savings, which is on top of the 181.33 hours per year of time savings."

Need help selecting a tool? Visit our online Tool Selector and go to the Locate Agent page on our website to find your local technical sales representative. For more assistance, contact us at info@heuletool.com or 513-860-9900 and we'll be happy to point you in the right direction.